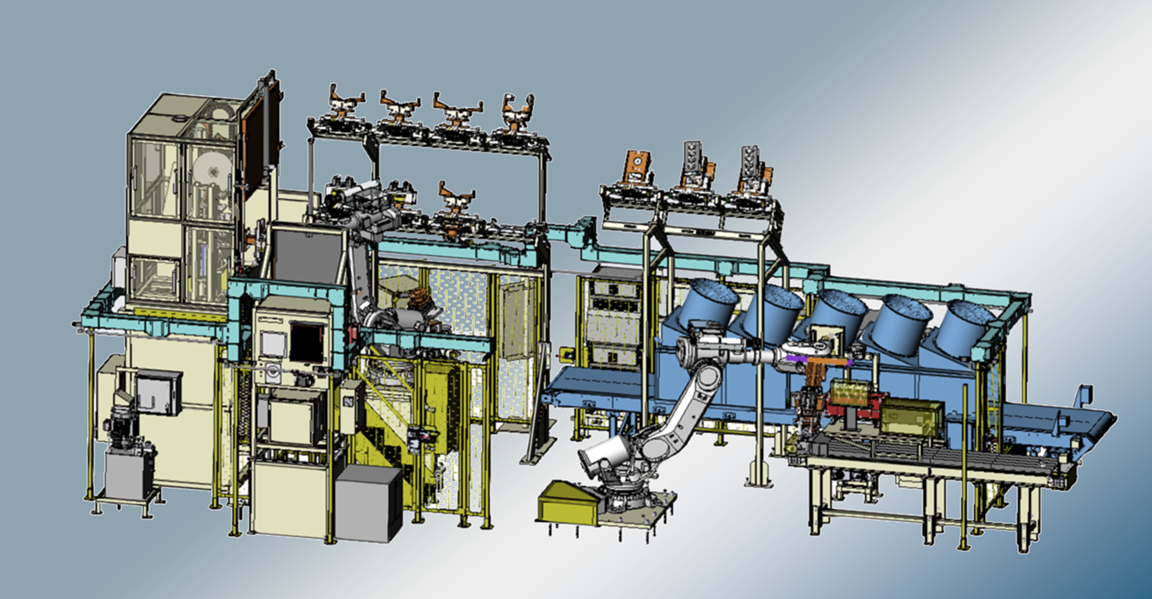

APPLICATIONS

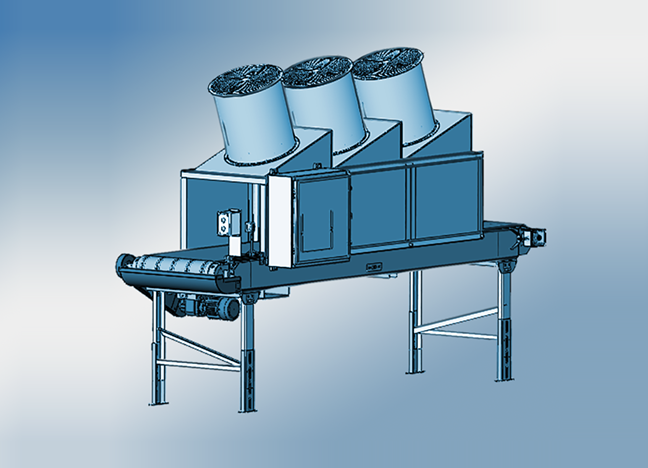

Air and Water Casting Coolers

ASD die-casting coolers are in-house engineered, designed and manufactured to fulfill your casting needs or built to your provided design specs.

Casting Coolers (Air & Water)

Our innovative team will design, engineer, fabricate, program, and install your automation system, cell, or integrated ancillary component. As a turnkey solution provider, we offer the ease of handling your system start to finish. Our in-house synergies reduce time, cost, and errors. Under one roof, our design-build capabilities ensure tested and programmed systems that are ready to run. Additionally, our full-service team can install, program, and test your system on-site.

ADVANTAGES

- Robust, reliability design and quality

- Quality test run and frequency measurement

- Precise cast cooling

- Effective cooling procedure

- Reduction of casting faults

- Automatic transport of the casts between shake-out and cleaning

- Minimum maintenance required

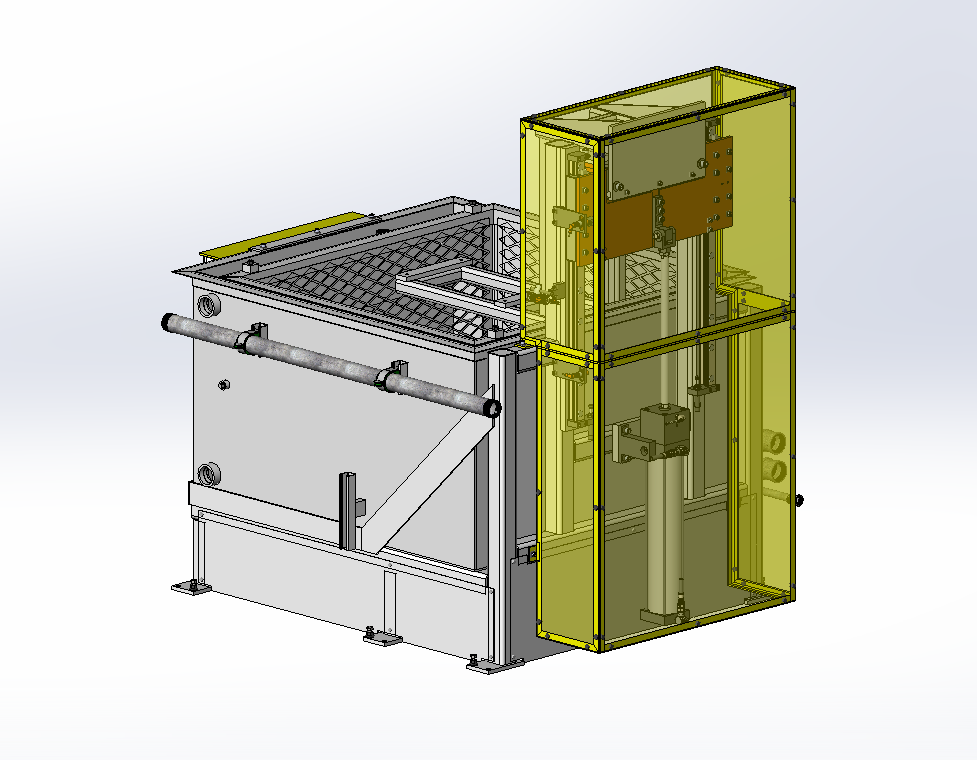

QUENCH TANK

OPTIONAL ELEVATOR LIFT

- By specification, ASD automatic pneumatic lift system is designed to raise and lower parts smoothly and safely with reduced tank cleaning downtime.

CONVEYOR FEATURES

- Vibrating conveyor with monitoring

- Two-mass system

- Drive shaft and V-belt drive systems

- Frequency converter

- Working springs

- Control cabinet

- PLC control

- Inflow air and outflow air nozzle

- Fresh air ventilator

- Water spraying